Have you ever thought about this?

- Tired of dealing with deoiling?

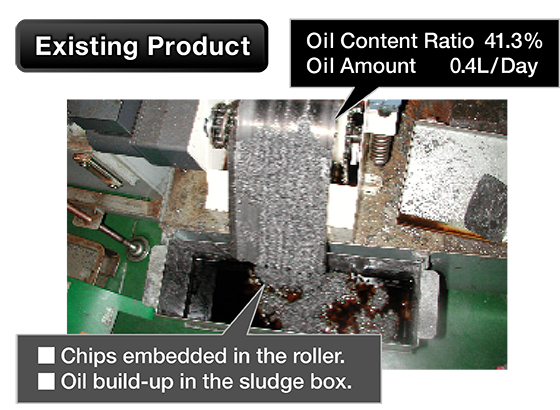

- Do you have problems with cutting chips embedded in rubber rollers?

For customers like this,

we strongly recommend the FineMag.

Problems that Customers Have.

- Squeeze rollers are embedded with chips even before one month of use.

- Squeeze rollers wear, resulting is bumps.

- Amount of oil adhering to chips is large.

- Oil accumulates in the sludge box, resulting in an increase in replacement oil amount.

- Because chips can not be wrung out, it is necessary to arrange more squeeze rollers.

These problems were

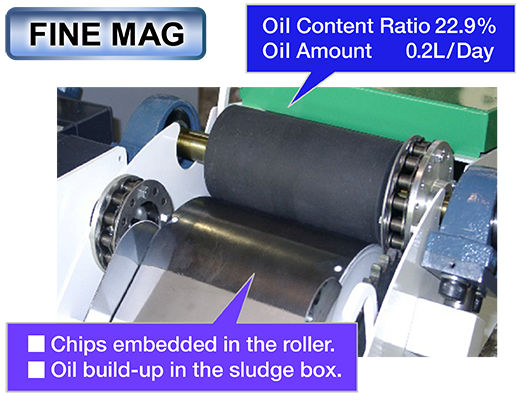

solved with the P-Roller and Newly Arranged Magnetic Drum.

What is the P-Roller?

Newly developed material that resists chip embedding, and improved oil resistance.

The result has been long-term stable squeezing.

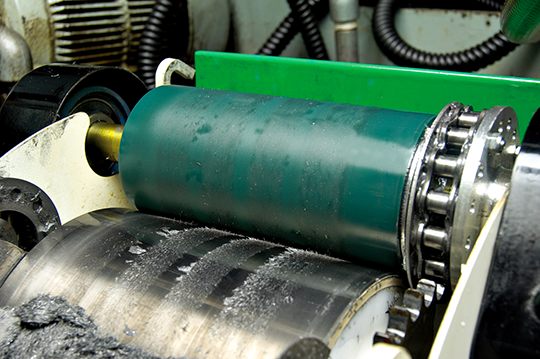

Also the Magnetic Drum itself.

An improvement over previous models, this FineMag features surface hardening, a magnetic drum surface that is highly accurate, which supports a long life even in shaving processing.