A strong ally to shaving processing.

Upon installing the FineMag, our deoiling work is zero! Productivity has been improved! Because of the P-Roller, our production facility has dramatically changed.

Installation Details, Results

We currently have 24 shaving machines in our facility.

Initially, we were using the magnetic separators that were installed on the shaving machines as auxiliary equipment.

In 2004, one of the magnetic separators broke down. We replaced it with one of the Sumitomo FineMags and its performance exceeded our expectations. We know have 20 FineMags.

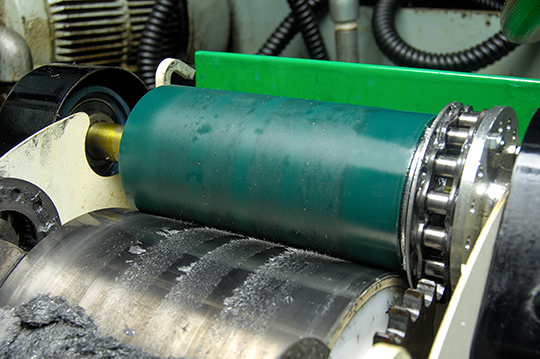

In 2006, we installed a newer version, the Model KS-4-1PX, which utilizes new magnetic drum and special rubber rollers (P-Roller). Its deoiling capability was fantastic.

In the past, the sticky wet chips that were discharged from the magnetic separator had to be placed into a centrifugal oil separator by a worker which took about one hour per day. The oil filled sludge box was very heavy and the deoiling process resulted in a very slick and dirty floor.

And of course the coolant in the tank soon ran low and had to be refilled frequently. In addition, the oil-based coolant recovered from the oil separator was filled with grit which caused wear on the pumps and cutters.

Upon employing the new model of FineMag that uses P-Rollers, the chips we used to get out of the deoiling equipment is now what is discharged from the FineMag. The deoling work is no longer necessary. Deoiling work and coolant replenishing work has been eliminated. Production is up, and the life of pumps and cutters has been increased dramatically. This has helped us very much. Coolant replenishing has also decreased by more than one drum per machine per year.

Compared to the older rollers that would go bad in about 3 because of embedded chips, the new P-Rollers, even after two years, perform as if they were new. Using the P-Roller type FineMag is a big advantage in the shaving industry.

Benefits of installation

- Deoiling efficiency is up resulting in increased productivity.

- Increased life of pumps and cutters.

- Reduction in coolant.

- Cleaning time reduced.

- Maintenance Free.

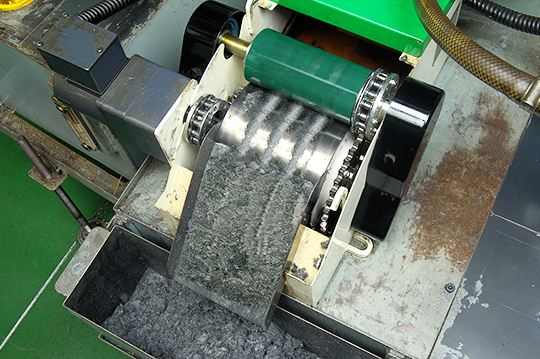

Our FineMag operating in the customer’s factory.

Customer information

Nagata Tekko Co., Ltd. Building a future through precision gears.

As a top company in precision gears, Nagata Tekko fills a variety of needs in many industries from large gears for machine tools, etc., to ultra-precision gears for office automation equipment, optical instruments, and household electrical appliances, as well as components for various drive trains.

| Headquarters・Factory | 1-12 Nogawa, Shukucho Toyokawa-Shi, Aichi-Ken 441-0101 TEL 81-533-72-2131 FAX 81-533-78-3616 |

|---|---|

| Sales | JPY 5,000,000,000 |

| Capital | JPY 76,250,000 |

| Employees | 165 |