Have you ever thought about this?

- How can we collect sludge which is difficult to magnetize?

- How can we collect fine magnetic metal powder?

For customers like this, we strongly recommend the FineMag.

Recommended reason

- Drum surface magnetic power of 9,000 gauss.

- The amazing 1.7 times higher filtration efficiency than model K.(Grinding sludge 5 to 15 μm)

- High performance for collecting sludge which is difficult to magnetize. (ex. Coolant for grinding cabide tools)

- High performance for collecting sludge which is difficult to magnetize. (ex. Honing/Lapping/EDM)

Product characteristics

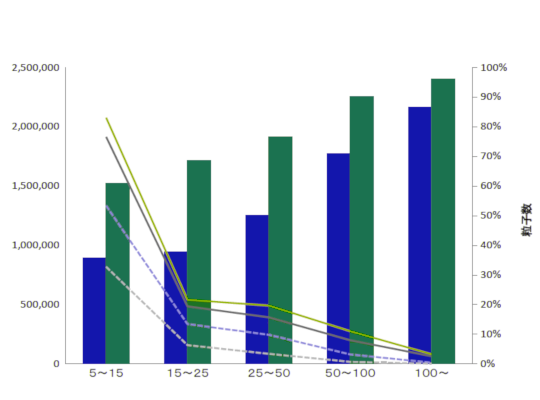

The amazing 1.7 times higher filtration efficiency than our standard model!

The amazing 1.7 times higher filtration efficiency than model K.(Grinding sludge 5 to 15 μm)

High performance for collecting sludge which is difficult to magnetize. (ex. Coolant for grinding cabide tools)

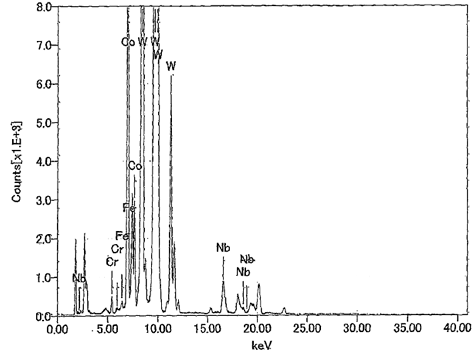

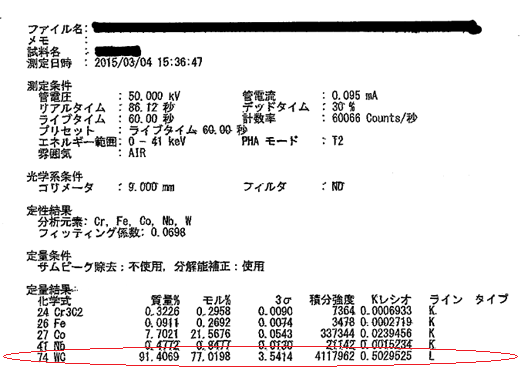

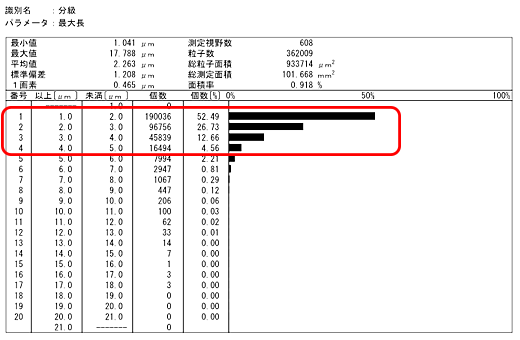

The volume of fine sludge less than 5 microns is more than 96%.

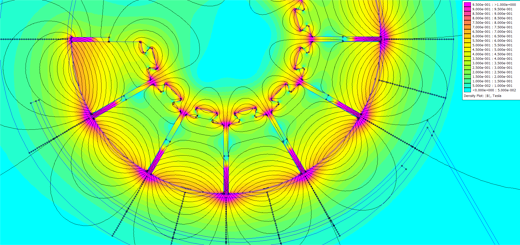

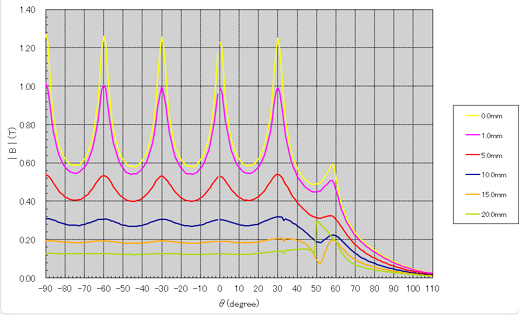

Repulsion magnetic circuit strengthen the magnetic power.

With the same basic structure as the magnetic separator for grinding machines, we have optimized the magnet arrangement in the drum. And succeeded to increase its surface magnetic flux density to 0.9T.

Ideal for the device to collect fine magnetic sludge

The UK FINE MAG can generate a high magnetic field, so it has great potential as a device for collecting fine magnetic metal powder.

In addition to the removal of the sludge which is generated from grinding process, it can be used as the recovery device of raw materials, or removal device of impure particles. FINE MAG has many other applications.

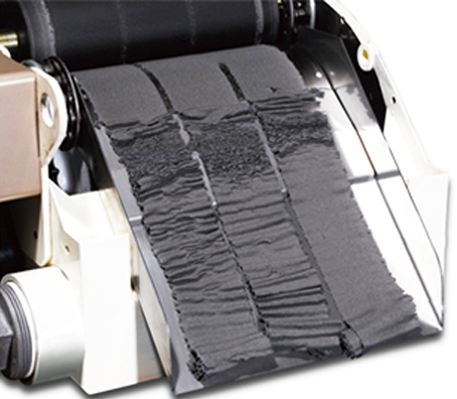

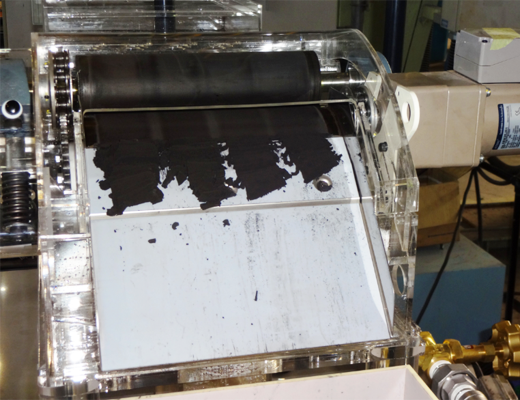

Magnetic sludge discharge condition

Improved productivity with continuous filtering

With the installation of UK FINE MAG, fine magnetic sludge can be collected continuously without suspending the production equipment.

UK FINE MAG

【Left: Dirty coolant before filtering】

【Right: Clean liquid after filtering】

Improved squeezing efficiency

Coolant can be squeezed from the magnetic sludge attracted by the UK magnet drum using rubber rollers and discharged to the sludge box.

No consumables required

Almost no need of maintenace and extra costs because consumables such as filters are not required.

- Reduce the load of secondary filters such as paper filter, diatomite filter, and line filter, substantially.

- Excellent sludge collecting capability that helps to Reduce significantly defects and the tank cleaning frequency. High squeezing performance ensures that the area around the machine is kept clean, contributing to the creation of a beautiful factory and better working environment.

- Sludge generated from grinding carbide tools and other materials that is hard to magnetize and fine sludge from honing or other processes can be collected.

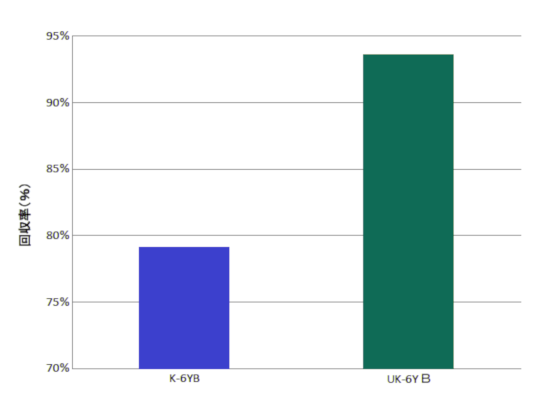

- Increase the value of carbide sludge as a recyclable resource due to a high collection rate and squeezing performance. (ex. tungsten carbide)