Sludge Recovery 7 Years of Operation with Zero Coolant Changeover

Bringing together the FineMag with our Coolant Cleaning Device reduced the burden on the machine and improved the efficiency percentage.

Installation Details, Results

In 1999, we built a factory at our Hirano Factory upon which customers could rely. We made a dry floor, and strove to build a clean factory with zero waste water. One part of our environmental activities involved conducting squeeze performance comparisons on magnetic separators in June 2004.

So that testing conditions were similar, we tested the FineMag and the magnetic separators of other companies using the same grinding machine and tank volume. The result of the test was that we know use about 30 FineMags.

Test conditions during magnetic separator performance comparison in 2004.

In addition, in our drive for more sustainability, we developed a grinding machine coolant cleaning device that incorporates the FineMag. The result is that coolant changeover has not been necessary in 7 years.

As a stand-alone machine, the FineMag employs an optimal magnet arrangement that results in a recovery of grit along with the magnetic sludge. Moreover, squeezing is done very well resulting in a liquid content less than 30%.

In addition, there have been no breakdowns. Not one claim from our factory employees. No worries or unsatisfactory feelings regarding after-sales service.

Benefits of installation

- Put together with our own Coolant Cleaning Device. No coolant changeovers.

- No breakdowns.

- Good squeezing down to under a 30% water content ratio which contributes to our internal company environmental improvement activities.

- Good after-sales service.

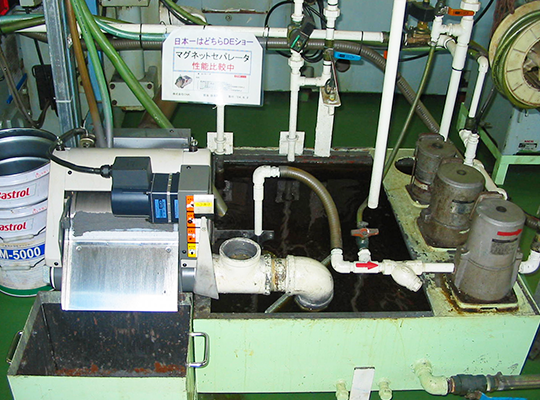

Our FineMag operating in the customer’s factory.

Customer information

Besq Co., Ltd.

Jiro Matsui, Director, Manufacturing Division.

Besq Co., Ltd., founded in 1952, began to actively incorporate a self-imposed environmental conservation and improvement program in 1999. Their factory is now considered a model-factory and green-factory both domestically and internationally, and hosts many visitors throughout the year. As we head into a period that recognizes the importance of environmental consideration, the factory of Besq Co., Ltd. is leading the way.

| Business Description | Production & Sales of Precision ・ Functional Parts of Two-wheel, Four-wheel, Marine Engine and Industrial Equipment. |

|---|---|

| Capital | JPY 34,000,000 |

| Employees | 210 (August 2010) |