FineMag for casting cutting processing.

We have installed 90 machines in 5 years, and could not function without them. Has greatly contributed to reducing our product reject rate and increasing the life of cutting coolant.

Installation Details, Results

Previously, we used a drum filter convey on our casting machining centers.In the case of cutting, are large amount of fine carbon chips are included which leads to frequent plugging of the high pressure pump and nozzles. Also, due to poor filtering accuracy, bad coolant is poured onto the workpieces and the product rejects are generated due to scratches.

In 2002, our grinding machine factory started to look for alternatives to the magnetic separators that were being used. Upon consulting with Sumitomo, they immediately offered demo machines upon which we started testing.

The result of two months of testing was that the life of the cutting coolant doubled and the number of rejected products decreased by 20%. We were quite surprised. We quickly bought one of the demo machines and installed it on one of our existing machining centers. We now have FineMags on each of our 90 machining centers.

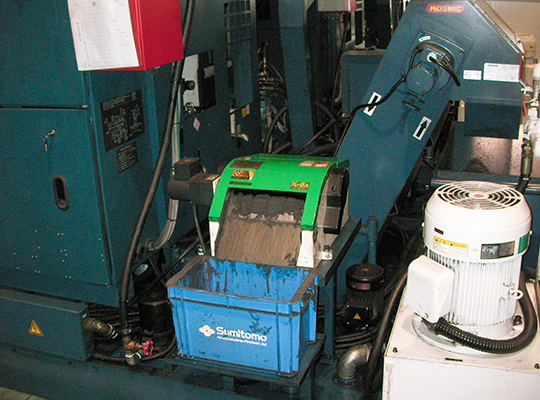

When cutting casting, we are employing the Model K type which uses high-power magnets. We recommend the FineMag as the shape of sludge from cutting is different form the sludge from grinding. The discharged is for the most part dry. Even after 6 years of use, the situation has not changed. We have not kept statistical data, but the we believe the life of the blades has been increased also.

There have been no breakdowns. I don’t remember ever buying any parts. It must seem like all I am just saying positive things, but that is the truth. If you try the FineMag even once, you will realize how good they really are.

Benefits of installation

- Life of cutting coolant doubled.

- Decrease in product rejects by 20%.

- Initial performance is maintained long-term.

- Maintenance Free

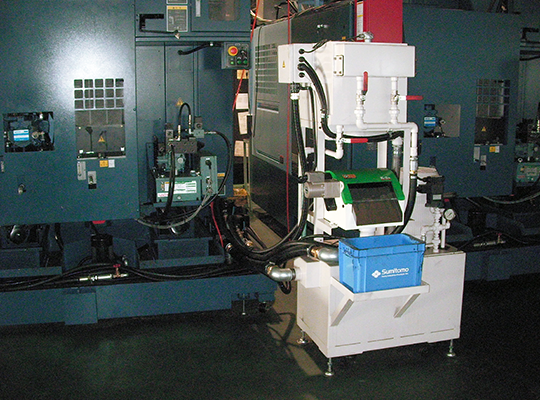

Our FineMag operating in the customer’s factory.

Customer information

| Business Description | Design, Development, Production and Sales of Directional Valves, Pressure Control Valves, Flow Control Valves, and Precision Gear Pumps. |

|---|---|

| Sales Amount | JPY 9,100,000,000 (Fiscal Year Ending 2007/09/30) |

| Capital | JPY 30,000,000 |

| Number of Employee | 220 |